When selecting a high-quality 1700℃ insulation castable for wholesale

Here are consider the following factors to ensure you choose a reliable product:

- Refractory Properties: Look for insulation castables specifically designed for high-temperature applications, with a temperature rating of 1700℃ or higher. Check the product specifications to confirm its suitability for your intended use.

- Insulation Performance: Evaluate the castable’s insulation performance, including its thermal conductivity and heat storage capacity. Low thermal conductivity and heat storage help minimize heat transfer and improve energy efficiency.

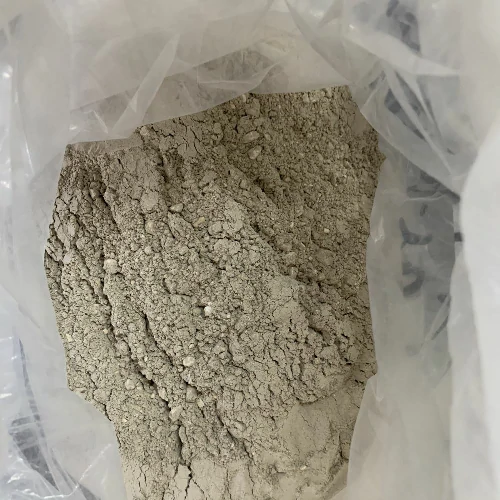

- Composition and Raw Materials: Examine the composition of the castable and the quality of the raw materials used. High-quality insulation castables typically contain premium raw materials that contribute to their performance and durability at high temperatures.

- Density and Porosity: Consider the density and porosity of the insulation castable. Optimal density and controlled porosity can enhance its insulating properties and resistance to thermal shock.

- Chemical Resistance: Ensure the castable has good chemical resistance to withstand the corrosive effects of various gases, liquids, or solids present in your specific application environment. Check if it meets the requirements for your application’s chemical exposure.

- Compressive Strength: Evaluate the compressive strength of the castable, as it should be able to withstand the loads and pressures associated with your application. Higher compressive strength indicates better structural integrity and durability.

- Bonding and Setting Properties: Assess the castable’s bonding and setting properties. It should have good workability during installation and form strong bonds to the substrate, ensuring a stable and secure lining.

- Supplier Reputation: Choose a reputable supplier with a track record of providing high-quality insulation castables. Research their reputation, customer reviews, and industry certifications to ensure their products meet the required standards.

- Technical Support: Consider the supplier’s technical support capabilities. A reliable supplier should offer assistance, guidance, and expertise in selecting and using the insulation castables, as well as provide support for installation and any troubleshooting needs that may arise.

- Price and Value: While price is a consideration, prioritize the overall value and quality of the insulation castable over solely focusing on the lowest price. Evaluate the cost-effectiveness of the product based on its performance, durability, and long-term benefits.

- Testing and Certification: Inquire about any testing or certification the insulation castable has undergone, such as ISO certification or compliance with relevant industry standards. This can provide assurance of its quality and performance.

It is recommended to consult with industry experts or refractory specialists who can provide specific guidance and recommendations based on your application requirements. They can help assess your needs, China 1700℃ Good Performance Insulating Castable wholesale compare different products, and make an informed decision on the most suitable high-quality insulation castable for your wholesale purchase.

Here are some additional details to consider when choosing a high-quality 1700℃ insulation castable for wholesale:

- Water Requirement: Check the water requirement of the castable, as it affects the ease of mixing, workability, and final properties of the castable after curing. It’s important to follow the manufacturer’s recommendations for water addition to achieve the desired consistency and performance.

- Curing and Drying Time: Understand the curing and drying time of the insulation castable. This information is crucial for planning and scheduling installation activities, as well as ensuring proper curing conditions to achieve optimal strength and performance.

- Application Method: Consider the application method recommended by the manufacturer. Insulation castables can be applied by vibration casting, pumping, or hand casting. Ensure that the chosen castable is suitable for the intended application method and equipment available.

- Packaging and Storage: Evaluate the packaging and storage requirements of the insulation castable. It should be packaged in moisture-resistant containers or bags to prevent moisture absorption, which can affect the material’s properties. Adequate storage conditions should be maintained to preserve the castable’s quality.

- Compatibility with Anchoring Systems: If your application requires anchoring systems for the castable lining, ensure that the chosen insulation castable is compatible with the anchoring methods and materials you intend to use. This will ensure a secure and reliable installation.

- Environmental Considerations: Assess any environmental factors that may impact the performance of the insulation castable. This includes considerations such as exposure to chemicals, gases, or abrasive particles, as well as any potential for thermal cycling or mechanical stress.

- Performance Data: Request performance data from the supplier, such as thermal conductivity, linear shrinkage, and thermal expansion characteristics. These data can help you compare different products and select the one that best meets your specific requirements.

- Quality Control: Inquire about the supplier’s quality control processes and whether they have certifications or quality management systems in place. This ensures that the insulation castable undergoes rigorous testing and meets consistent quality standards.

- Customization and Bulk Ordering: If you have specific requirements or need a large quantity of insulation castable, check if the supplier offers customization options or bulk ordering discounts. This can help tailor the product to your needs and potentially reduce costs.

Remember to thoroughly research and evaluate different suppliers, request samples for testing, and compare multiple options before making a decision. Working closely with reputable suppliers and seeking expert advice can help ensure you choose a high-quality 1700℃ insulation castable that meets your application’s requirements and provides long-lasting performance.