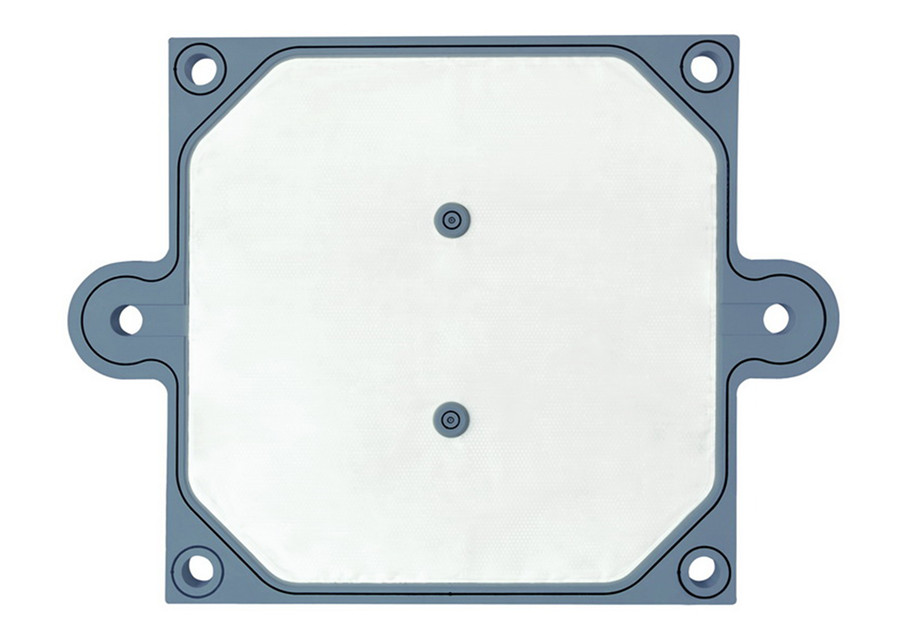

A used beer plate filter is a piece of equipment that is commonly used in the brewing industry to filter beer and other beverages.

Here are some important things to know about a used beer plate filter:

Condition: When purchasing a used beer plate filter, it’s important to check its condition. Look for any signs of damage, corrosion, or wear and tear that could affect its performance. Make sure that all the parts are intact and functioning properly.

Size: Beer plate filters come in different sizes, so it’s important to choose one that suits your brewing needs. Consider the volume of beer you need to filter and choose a filter that can handle that capacity.

Compatibility: Beer plate filters are designed to work with specific types of beer or beverages. Make sure that the filter you choose is compatible with the type of beer that you are brewing.

Maintenance: Regular maintenance is important to ensure the longevity and efficiency of the filter. Check the manufacturer’s instructions for recommended maintenance procedures.

Operating Pressure: Beer plate filters operate under pressure, so it’s important to choose a filter that can handle the pressure requirements of your brewing process. Check the manufacturer’s specifications for the operating pressure of the filter.

Filter Media: Beer plate filters use different types of filter media such as diatomaceous earth or cellulose pads. Choose a filter media that is appropriate for the type of beer you are brewing.

Cost: Used beer plate filters can be a cost-effective option for breweries on a budget. However, it’s important to consider the overall cost of the filter, including any necessary repairs or maintenance.

By considering these factors, you can make an informed decision when purchasing a used beer plate filter for your brewing operation.

How to Buy the Right beer plate filter?

Buying the right beer plate filter is important to ensure that your brewing operation produces high-quality beer.

Here are some factors to consider when buying a beer plate filter:

Size: Consider the volume of beer you need to filter and choose a filter that can handle that capacity. Beer plate filters come in different sizes, so choose one that suits your brewing needs.

Material: Beer plate filters are typically made of stainless steel or plastic. Stainless steel filters are more durable and long-lasting, while plastic filters are more affordable and lightweight.

Compatibility: Beer plate filters are designed to work with specific types of beer or beverages. beer plate filter Make sure that the filter you choose is compatible with the type of beer that you are brewing.

Filtration Efficiency: The filtration efficiency of a beer plate filter is measured in microns. Choose a filter that has a micron rating that is appropriate for the type of beer you are brewing.

Maintenance: Regular maintenance is important to ensure the longevity and efficiency of the filter. Check the manufacturer’s instructions for recommended maintenance procedures.

Operating Pressure: Beer plate filters operate under pressure, so it’s important to choose a filter that can handle the pressure requirements of your brewing process. Check the manufacturer’s specifications for the operating pressure of the filter.

Cost: The cost of the filter should be considered, including any necessary repairs or maintenance. Choose a filter that fits within your budget without compromising on quality.

Brand Reputation: Choose a beer plate filter from a reputable brand with a good track record in the brewing industry. Check reviews from other brewers to gauge the quality and performance of the filter.

By considering these factors, you can buy the right beer plate filter for your brewing operation and produce high-quality beer